BELTROTHERM DRYER CONCEPT

-

Predrying after soldermask coating

Predrying after soldermask coating

read more...

BELTROTHERM V-belt dryer for predrying after wet lacquer coating.

This unique drying technology allows evaporation and predrying of coated wet lacquers i.e. soldermask, etch resist etc. within 5 to 7 minutes.

The surface is pre-dried tack-free and residue-free development after exposure ensured...

-

Evaporation and drying

Evaporation and drying

after wet lacquer coating

read more...

BELTROTHERM belt dryer for evaporation and drying after wet lacquer coating.

All colors, lacquers and products applied by wet coating process are dried in horizontal continuous process single or double-sided.

Type of heat sources, air flow, temperature, evaporation and drying times to be adapted to the requirements...

-

Final Curing photo soldermask

Final Curing photo soldermask

after exposure and developement

with UV-bump before

Double-sided Final Curing Line for soldermaskPos 1: Feeder

Pos 2: UV-bump double-sided

Pos 3: BELTROTHERM-dryer doulbe-sided

Pos 4: StackerThe line is working fully automatic after loading in 3-shift operation without supervision...

read more...

-

Drying after full surface screen printing horizontally or vertically

Drying after full surface screen printing horizontally or vertically

Full surface screen printingHorizontal screen printed liquid coatings are manually or automatically fed to the pre-dryer BELTROTHERM. Depending on the required drying program evaporation and drying of the ink is made to the adhesive-free further processing...

read more...

-

Drying of screen printing products

Drying of screen printing products

after partial screen printing

read more...

Partial screen printing is still widespread application when printing:

Label colors, strippable coatings, carbon paste, silver paste, hole filling pastes, soldermask partially, adhesion promoters, heatsink-paste, ceramic materials, etc...

-

Drying of printed electronics

Drying of printed electronics

and membran switches

The BELTROTHERM belt dryerparticularly suitable for the drying of metal paste and isolation materials used in the production of printed electronics. The long-wave infrared radiation in combination with the convection air heat drying metallic pastes from inside to outside, thereby avoiding skin formation on the surface...

read more...

-

Dryer for photovoltaics, thin film production, hybrid technology

Dryer for photovoltaics, thin film production, hybrid technology

BELTROTHERM continuous dryer

with a flat belt transport.IIn photovoltaics, thin film and hybrid technology thermally drying materials are frequently used and dried after coating. The BELTROTHERM continuous dryer with a flat conveyor belt transports and dries the coatings quickly and efficiently...

read more...

-

Evaporation and drying e.g. after spray coating of photosensitive solder resist

Evaporation and drying e.g. after spray coating of photosensitive solder resist

BELTROTHERM belt dryer for evaporation and drying after spray coating.This unique drying technology allows evaporation and drying of a spray-coated solder masks single- and double sided within 5 to 7 minutes.

The surface is pre-dried tack-free and ensures residue-free development after exposure...

read more... -

Evaporation and predrying after coating of photosensitive solder resist by curtain-coating

Evaporation and predrying after coating of photosensitive solder resist by curtain-coating

BELTROTHERM belt dryer for evaporation and drying after curtain coating.This unique drying technology allows evaporation and drying of curtain-coated solder resists unilaterally within 6 to 8 minutes.

The surface is pre-dried tack-free and ensures residue-free development after exposure...

read more... -

Evaporation and predrying after coating of photosensitive solder resist by single or double-sided screen printing

Evaporation and predrying after coating of photosensitive solder resist by single or double-sided screen printing

BELTROTHERM belt dryer for evaporation and drying after screen printing.This unique drying technology allows evaporation and drying of curtain-coated solder resists unilaterally within 6 to 8 minutes. The surface is pre-dried tack-free and ensures residue-free development after exposure...

read more...

-

Evaporation and predrying after coating of photosensitive solder resist by vertically double-sided screen printing

Evaporation and predrying after coating of photosensitive solder resist by vertically double-sided screen printing

BELTROTHERM belt dryer for evaporation and drying after screen printing.This unique drying technology allows evaporation and drying of curtain-coated solder resists unilaterally within 6 to 8 minutes. The surface is pre-dried tack-free and ensures residue-free development after exposure...

read more... -

Infrared (IR) dryer for thermal and IR drying inks and materials with long-, medium-and short-wave infrared radiation source

Infrared (IR) dryer for thermal and IR drying inks and materials with long-, medium-and short-wave infrared radiation source

read more...

BELTROTHERM continuous drier for the infrared drying of the coating of different flat materials with infrared reactive substances. This unique drying technology allows the drying of coated paints and coating material within minutes. Depending on the drying equipment the process is running single or double-sided... -

UV bump with parallel belt transport

UV bump with parallel belt transport

Recommended by lacquer manufacturers!

read more...

UV bump with parallel belt transport for mass production of printed circuit boards and especially sensitive materials, flexible circuit boards and membran switches...

-

UV bump double-sided for solder resists

UV bump double-sided for solder resists

Low maintenance and versatile!

UV bump with metal-grid belt conveyor for mass production of printed circuit boards and substrates...

read more...

-

UV bump double-sided for solder resists

UV bump double-sided for solder resists

Extremely short at full power!

UV bump with metal grid belt transport in special design Slimsize requires minimal space, often used in production lines...

read more...

-

UV dryer with belt transport for single side assembled printed circuit boards

UV dryer with belt transport for single side assembled printed circuit boards

Standard belt model, versatile, low maintenance, durable!

read more...

For the UV curing of thick-film protective coatings on one side printed board assemblies / sub-assemblies, as well as other UV products, such as UV-thick layer of protective lacquer TWIN CURE ® Lackwerke Peters or Corp.9481 Dymax and other UV curing products...

-

UV dryer with drawer

UV dryer with drawer

Safe for the operator quickly and reliably!

read more...

The UV dryer BELTROSTAT serves for uniform drying and curing of UV coatings and is particularly suitable for use in the production of small series, with repairs and in the laboratory. The device is optionally equipped with a timer with function keys or a control computer BELTROMAT... -

UV-box dryer

UV-box dryer

Also ideal for extremely high assembled PCBs or substrates!

read more...

Applications of UV irradiation chamber are varied. In addition to the usual tasks, such as curing and bonding, the chamber can also be used for material aging tests and irradiation for chemical and biological applications... -

UV dryer with pin chain conveyor for protective paint coatings on single and double sided assembled PCBs

UV dryer with pin chain conveyor for protective paint coatings on single and double sided assembled PCBs

Single-and double-sided use, fast and flexible!

read more...

UV curing of all UV-reactive materials, such as protective coatings, adhesives, resins and UV coatings on double sided printed circuit boards / assemblies. Suitable for fully automatic inline operation... -

LED-UV curing BE 15

LED-UV curing BE 15

Recent development, energy saving, with cold light!

read more...

UV curing drying inks, printing inks, coatings, adhesives and other UV-sensitive materials by polymerization instead of evaporation of solvents. Until now conventional mercury UV lamps were used for the curing. But UV-LED sources open additional possibilities... -

LED-UV curing BE 20

LED-UV curing BE 20

Recent development, energy saving, with cold light!

read more...

UV curing drying inks, printing inks, coatings, adhesives and other UV-sensitive materials by polymerization instead of evaporation of solvents. Until now conventional mercury UV lamps were used for the curing. But UV-LED sources open additional possibilities... -

LED-UV curing BE 7

LED-UV curing BE 7

Recent development, energy saving, with cold light!

read more...

UV curing drying inks, printing inks, coatings, adhesives and other UV-sensitive materials by polymerization instead of evaporation of solvents. Until now conventional mercury UV lamps were used for the curing. But UV-LED sources open additional possibilities... -

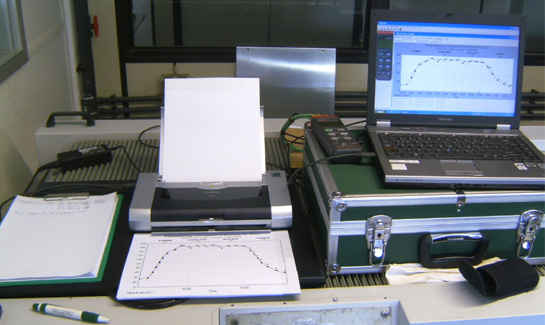

UV-Integrator Typ I

UV-Integrator Typ I

read more...

Areas of application:

The BELTRON UV integrators are used to record UV energy in UV curing, UV drying ovens...

-

UV-Integrator Typ D

UV-Integrator Typ D

read more...

Areas of application:

The BELTRON UV integrators are used to record UV energy in UV curing, UV drying ovens...

-

UV-Meter

UV-Meter

read more...

Areas of application:

Meters for simple intensity and control measurements in the UV range. All types of special UV ranges ...

-

Temperature measuring device for temperature profiles

Temperature measuring device for temperature profiles

read more...

Areas of application:

Simple and convenient unit for measuring temperature profiles in horizontal continuous dryers...

-

Flextrans ® support frame

Flextrans ® support frame

read more...

The Flextrans ® support frame represents an entirely new method for handling flexible printed circuit boards and materials during a single and doulbe-sided coating process, e.g. Spray coating or curtain coating. The simplicity of the system features is unique and makes working in the coating of flexible printed circuit boards easy and inexpensive...

DRYER FOR COATING LINES

INFRARED DRYER

MINUTES DRYING, FLEXIBLE!

UV DRYER

UV DRYING PROCESSES HAVE MANY BENEFITS!

LED-UV DRYING

LATEST DEVELOPMENT, ENERGY SAVING WITH COLD LIGHT!

TEMPERATURE AND UV MEASURING

EASY TO USE, GOOD PRICE!

HANDLING TECHNOLOGY

FOR FLEXIBLE PRINTED CIRCUIT BOARDS AND FLEXIBLE MATERIALS

UNIQUE SYSTEM, EASY HANDLING!

| CONTACT | TOP-PRODUCTS | QUICKLINKS |

ELGET Engineering Office Phone +49 (0) 911 529 96 20 Email elget@elget.de Managing Director: |

| © by Elget Ingenieurbüro - Concept and Design by media-illusion |