|

BELTROTHERM continuous belt dryer for evaporation and predrying after spray coating.

This unique drying technology allows evaporation and drying of a spray coated solder masks single- and double sided within 5 to 7 minutes.

The surface is pre-dried tack-free and ensures residue-free development after exposure. For double-sided process the dryer is equipped with V-belt transport.

The drying process is independent of the type of coating and on one side or two-side coating. The pre-drying and evaporation occurs in the horizontal method, quickly and completely.

The BELTROTHERM drying concept is suitable for single-sided or double-sided screen printing horizontal or vertical, curtain coating, single-or double-sided spray coating, dip coating, roller coating, and more.

| |

Click on the images to enlarge... Click on the images to enlarge... |

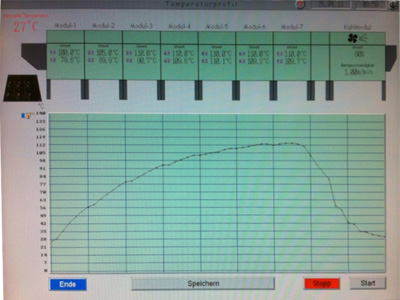

For different PCB thickness ranges and special types temperature profiles - tuned to an optimal drying process – will be created and stored in the PLC. Optimized temperature profiles are recorded and stored in up to 120 programs.

The appropriate drying program is called by touch on the touch screen and changed within minutes. The few minutes changeover usually go into the preparation of the coating line for the new lot. The operational readiness will be reported by signal to the upstream machine. The touch screen OMRON PLC shows a clear view of the operation condition and is ready for more input.

| |

We are happy to inform you about our products and services.

Phone: +49 (0) 911 529 96 20 or by email: elegt@elget.de |

|